New methods of simulation for additive manufacturing

The aim of the project was to simulatively predict the formation of the microstructure of additive-manufactured titanium components.

In powder bed based laser beam melting many different factors play a role in creating a component. In addition to the system parameters, the protective gas atmosphere, the orientation of the component in the installation space and the designed geometry of the components can also be relevant.

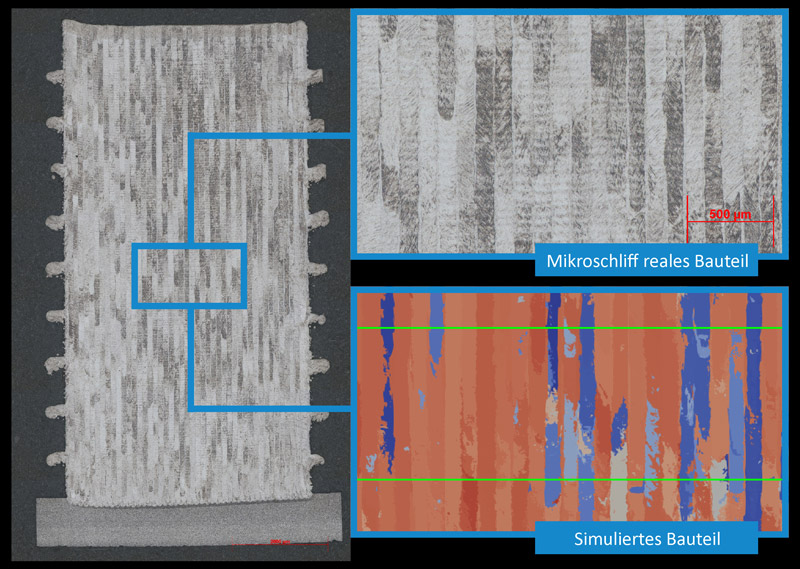

In the SimKorn project, the research partners jointly developed a simulation method which takes all these factors into account and which can be used to represent the construction process of additively manufactured parts for the material TiAl6V4. The results of the simulation were experimentally validated in the project. For this purpose, the simulated components were manufactured in real life. Subsequently, microstructure images were generated and compared with the simulation data.

At the end of the project, a reliable simulation method for the microstructure formation during the powder bed based additive manufacturing of titanium components has been developed. The SimKorn project thus forms the basis for further investigations into process simulation. In the following research projects, further materials are now to be simulated, thus extending the simulation model.

For industrial companies, reliable simulation methods would make it considerably easier to use and implement additive manufacturing processes, because process results can be predicted in a time- and cost-efficient manner.

The project was funded by the German Federal Ministry of Economics and Energy in the Joint Industrial Research Centre (IGF).