Quality assurance in additive manufacturing

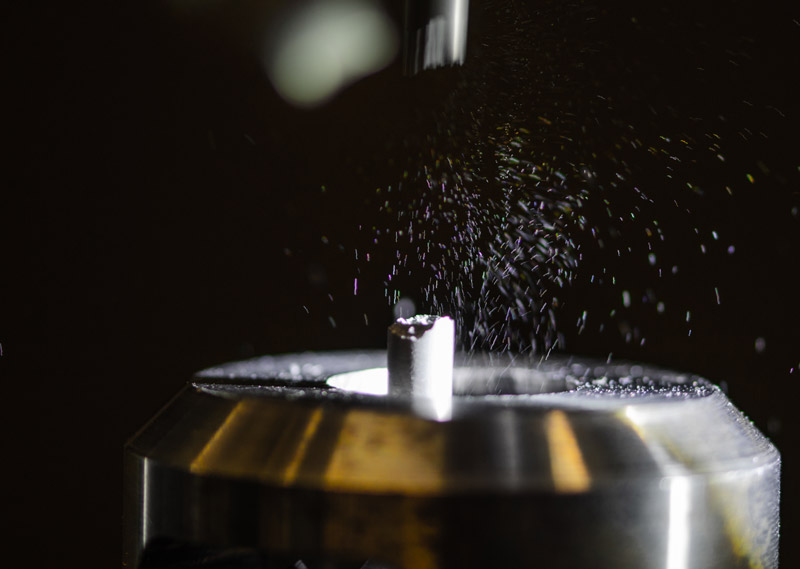

For this purpose, sample parts are produced at the institute by additive manufacturing and deliberately provided with defects of different sizes. Subsequently, these defective samples are dynamically tested in the materials testing laboratory and the influence of the different defects on the mechanical properties of the samples is determined.

The investigations are based on the results of the QuaPla project, in which possible sources of error in additive manufacturing were identified and the manufactured samples were statically tested.

Finally, the results of the project should provide information about the extent to which defects in additively manufactured components are tolerable. By means of the controlled introduction of defects and the subsequent material tests, characteristic values can be found which enable binding standards for quality assurance in metallic components manufactured using additives to be established.

The project is funded by the Federal Ministry of Economics and Energy in the INNO-KOM programme.