Additive Processing of amorphous metals

The aim of the project is to additively process Bulk Metallic Glasses using the PBF-LB process. This makes it possible to produce lightweight components that are both highly resilient and elastic. This can be used, for example, to manufacture additively manufactured solid-state joints or hydrogen tanks for the aerospace industry.

In order to determine optimal processing parameters, additively manufactured samples of amorphous metals are tested at the institute for their load-bearing capacity. The investigations are intended to use the novel material to surpass the weight-specific strength of other additively processable alloys. Compared to the state of the art, lighter components could thus be produced.

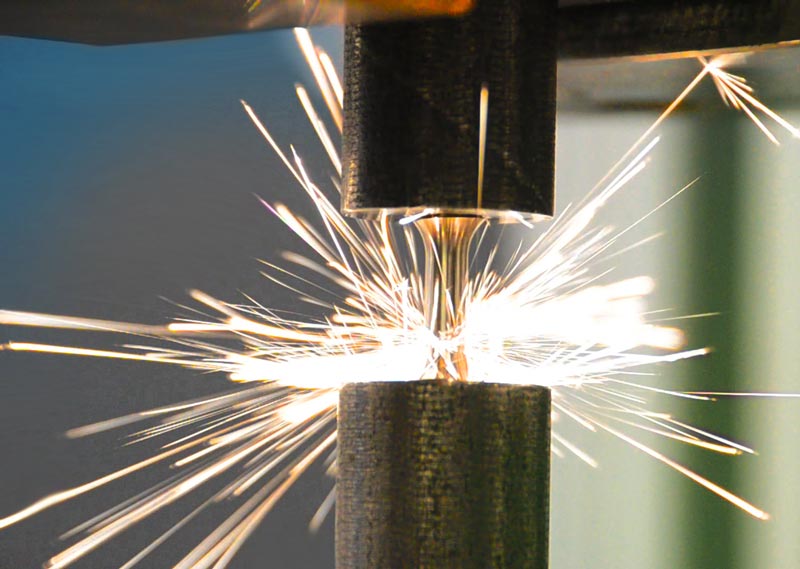

Two special features immediately catch the eye during tensile testing: unlike crystalline metals, amorphous metals crack simultaneously in two places. The resulting temperatures are so high that sparks occur.

In the project, the processing of the amorphous materials is investigated in several steps: First, dense samples are fabricated and tested to find suitable parameters for additive manufacturing. Then, samples with sufficient mechanical parameters will be fabricated to meet the requirements for future components. Finally, a hydrogen tank for space applications will be manufactured using the developed process to demonstrate the potential of the material.

Tanks of this type have so far been made of titanium alloys. A tank made of Bulk Metallic Glass would be more resistant to high pressure due to its high strength. Thanks to the possibility of producing thin-walled components in the PBF-LB process, it would also offer more volume than a comparable tank made of a titanium alloy.

Powder bed-based additive processes are particularly suitable for these materials: the rapid cooling of the material after melting makes it easy to achieve the amorphous structures. Likewise, fine structures and thin-walled components can be precisely manufactured using the process. The process thus supports the special properties of amorphous metals and makes optimum use of them for the final components and their applications.

The project is funded by the German Federal Ministry of Economics and Climate Protection in the INNO-KOM program.