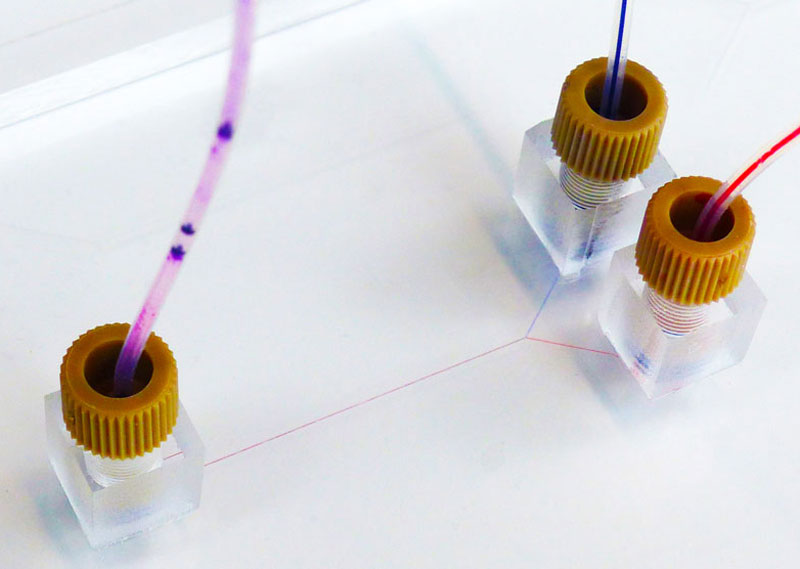

PMMA as a new material for large sized microfluid applications

Until now, most microfluidic devices have been made from rigid materials such as glass, silicone or the polymer PDMS.

Thanks to its processing options and recyclability, PMMA represents an economical alternative to existing materials. Due to its lower weight and higher breaking strength, appliances made of PMMA are also easier to handle.

In the PMMA joining project, various processing methods were investigated in order to determine how PMMA can be processed economically. The findings should enable companies to manufacture equipment for microfluidic applications more cost-effectively and with fewer resources.

On the one hand, the project investigated which process can be used to create channels with diameters of 75 to 175 µm in the material and how large-format PMMA components can be joined together.

At the end of the project, it became clear that laser processing with ultrashort laser pulses is ideally suited to inserting the intricate channels into the material. Diffusion bonding proved to be the optimal joining process - PMMA components can be joined together with a material bond without impairing the geometry of the previously inserted channels or the properties of the material.

The knowledge gained from the project will benefit manufacturers in particular: by investigating and optimizing the manufacturing processes, equipment for microfluidic applications can also be produced economically from PMMA in the future. This will enable manufacturers to expand their portfolio and use PMMA as a new material for their production.