ADDITIVE MANUFACTURING PBF-LB, MEX, FDM

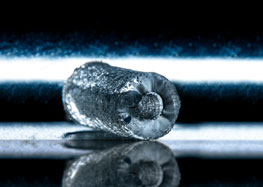

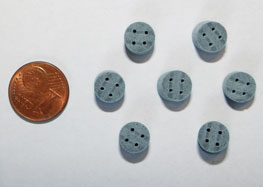

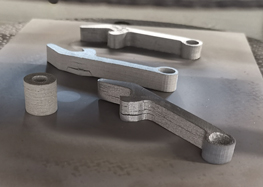

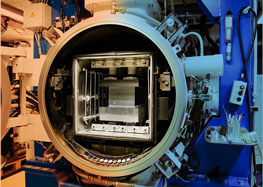

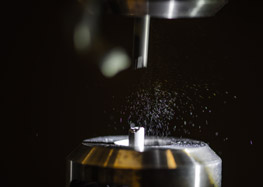

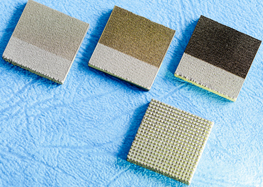

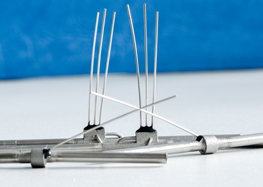

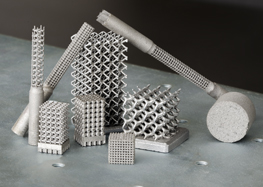

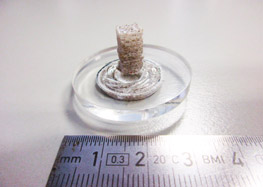

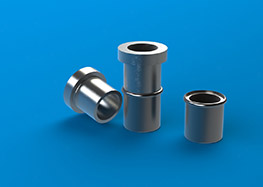

Additive manufacturing – also known as 3D printing – opens up a whole new range of possibilities for development, construction and manufacturing. Research conducted at ifw Jena focuses mainly on the optimization and further development of Selective Laser Melting (SLM).

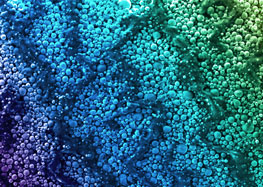

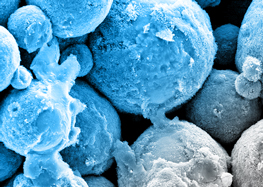

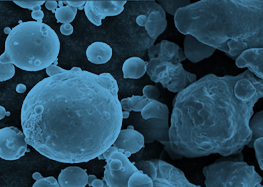

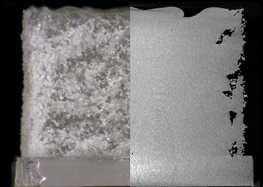

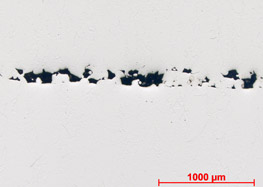

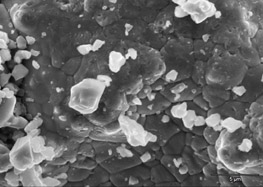

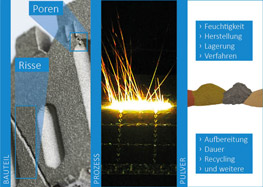

The qualification and parameter optimization for new materials, as well as the investigation of process details such as the effects of environmental influences on both raw powder and the process itself are particularly relevant research topics within this field.

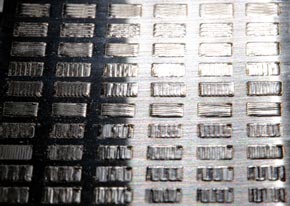

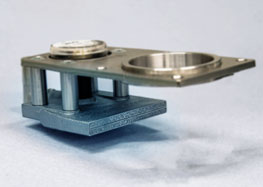

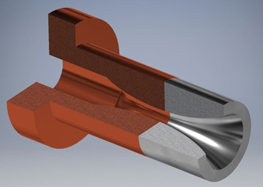

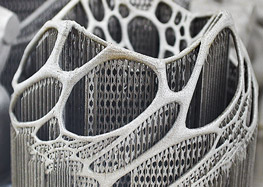

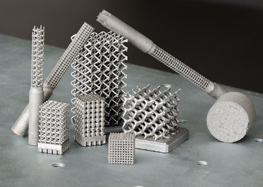

Selective laser melting holds plenty of advantages over conventional manufacturing techniques.

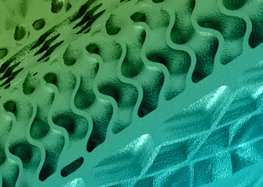

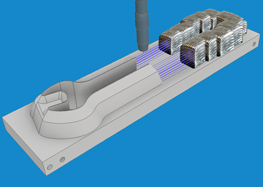

The most decisive among these is the high geometric freedom, as it enables functional integration (e.g. of cooling channels or undercuts). The use of minimized process chains, as known from Rapid Prototyping processes such as Rapid Tooling or Rapid Manufacturing shortens throughput times significantly. Also the raw material consumption is reduced, enabling optimal use of resources. Due to their reduced weight, additive-manufactured components are an ideal solution for lightweight constructions.