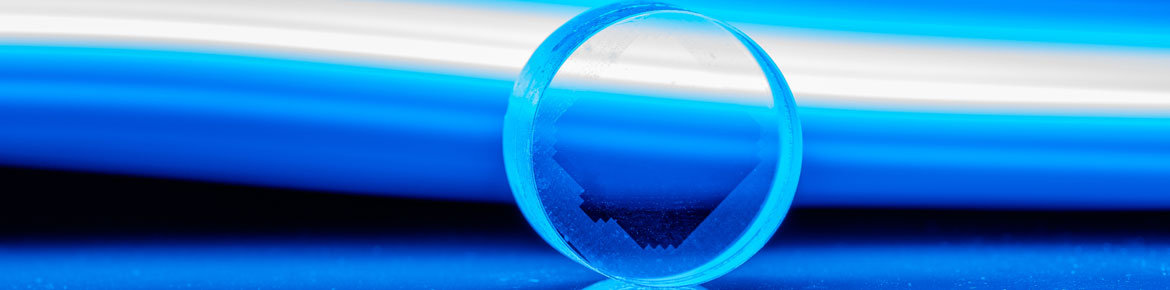

Glas Layer Weld

Förderkennzeichen: 2025 VDY 0019

Projektlaufzeit: 01.08.2025 bis 31.07.2026

Technology development for gap-filling laser welding

The aim of the project is to develop a technology in which the welding of glass using ultrashort pulse lasers through water glass is investigated and brought to industrial maturity.

The advantages of both processes are to be exploited: water glass as a gap filler and contact mediator, and USP welding to produce highly stable joints. The high demands on the surface quality of the joining partners for USL welding are to be reduced through the use of water glass. In comparison, Optec Jena GmbH will use cold putty as a contact agent. The test specimens produced in this way will also be welded using USL at ifw Jena in the further course of the project.

As part of the project, the possibility of using the proposed methods to embed functional layers such as highly reflective or polarizing layers between two joining partners made of glass with maximum mechanical strength will also be investigated.

The advantages of both processes are to be exploited: water glass as a gap filler and contact mediator, and USP welding to produce highly stable joints. The high demands on the surface quality of the joining partners for USL welding are to be reduced through the use of water glass. In comparison, Optec Jena GmbH will use cold putty as a contact agent. The test specimens produced in this way will also be welded using USL at ifw Jena in the further course of the project.

As part of the project, the possibility of using the proposed methods to embed functional layers such as highly reflective or polarizing layers between two joining partners made of glass with maximum mechanical strength will also be investigated.

Project partner: Optec Jena GmbH