SamurAi

Förderkennzeichen: ZF4236507TV8

Projektlaufzeit: 01.01.2019 bis 31.12.2019

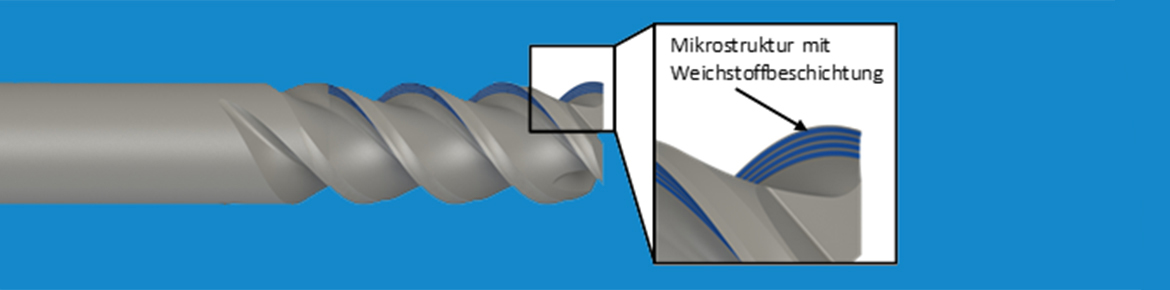

Simulation-based development of micro structured molding cutters with innovative friction reducing soft-material coating for processing of aluminium

The objective of the research project is the development of an innovative molding cutter that minimizes the friction between the tool and the chiping. It is intended to develop a shank molding cutter for machining aluminum materials with a coating system made of hard and soft materials as well as micro-structuring on the rake face. The microstructures serve as lubricant bearings and continuously release the solid lubricant during the machining process. With the new tool, it will be possible to dispense with conventional flooding lubrication in aluminum machining and to make dry machining more usable.

Project part

Development of a technology for the positioning and tracking of molding cutters for the production of microstructures on twisted rake faces by means of UKP lasers and coding of test tools.