WELDING

Laser welding

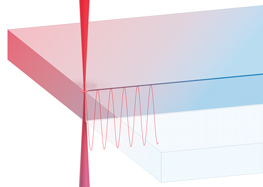

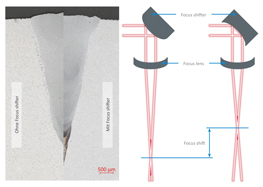

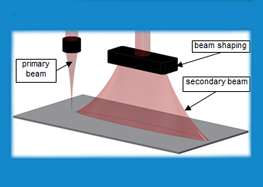

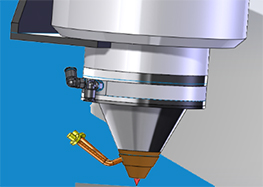

Laser beam welding is a technique whereby semi-finished products are melted by means of of a laser beam in order to achieve firmly bonded components. Due to the intensity of the beam, a high energy input into the material takes place within an extremely limited area and with minimal thermal input. The result is a welding seam with a high aspect ratio (in depth and width) and a very small heat-affected zone. Also, due to the low thermal input, laser beam welded components present a considerably lower warpage than conventionally welded ones.

Our research focuses mainly on welding of thin-walled structures made either of multiphase steels or of dissimilar metal mix compositions.

Dr.-Ing. Johannes Günther +49 3641 204-124 E-Mail schreiben

Arc welding

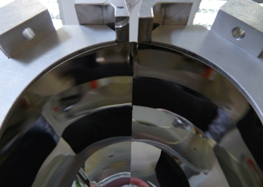

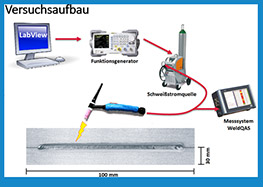

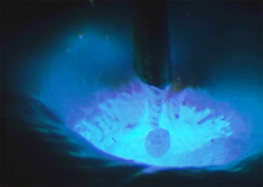

Arc welding is a welding technique which uses electricity to join metals. An electric arc is created between an electrode and the joint between two metal parts. An intense heat is produced causing the joint between the two parts to melt and the metals to intermix. The welding process can be carried out either directly (i. e. part-to-part) or by adding an intermediate filler metal with similar a melting point. Our research work at ifw Jena focuses primarily on Shielded Metal Arc Welding (SMAW) and on Gas Tungsten Arc Welding (GTAW).

Shielded Metal Arc Welding (SMAW), as a manual arc welding process, can be further divided into two subcategories: Metal Active Gas welding (MAG) and Metal Inert Gas welding (MIG). The necessary heat is produced by an electric arc formed between the base material and a consumable electrode. Additionally, a shielding gas is released during the process in order to protect the weld area from atmospheric contamination.

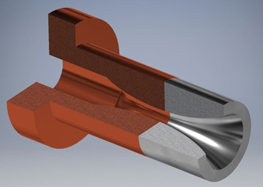

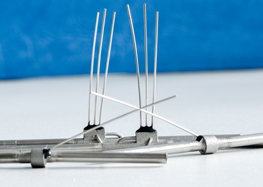

In Gas Tungsten Arc Welding (GTAW) the heat for welding is generated by an arc created between a non-consumable tungsten electrode and the workpiece. The filler material is fed into the electric arc where it melts. An inert gas shields the glowing tungsten electrode, the welding pool and the surrounding area preventing contamination from atmospheric gasses.

The limited thermal capacity of the tungsten electrode has advantages as well as disadvantages. The major drawback of GTAW is that it lowers deposition rates and reduces welding speed. On the plus side, however, it allows the subsequent modeling of the weld seam in case of an imprecise seam preparation.

The following themes are currently being researched at ifw Jena with regard to their applicability and their impact on the quality of the welding seam:

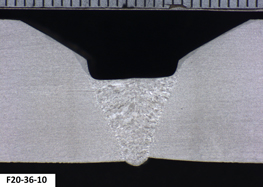

- new welding procedures such as Wolfram Inert Gas (WIG) - Plug Welding

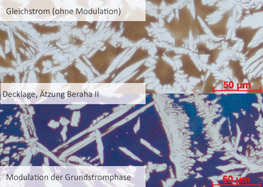

- modified electric arcs

- new materials

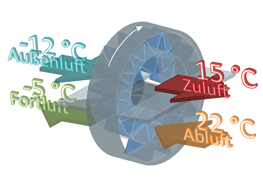

- alternative mixtures of shielding and forming gases

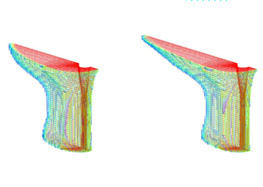

specific welding seam geometrics