SLM-Flex

Förderkennzeichen: VF150016

Projektlaufzeit: 01.02.2016 bis 31.07.2018

Development of flexible thin-walled components using laser beam melting

In order to be able to manufacture thin-walled components, a multitude of process influences must be taken into account. The project focuses on the evaluation of a suitable parameter set for the generation of thin-walled (<1 mm) components (including laser power (PL), scanning speed (vS), track spacing (SA) and layer thickness (dS)) as well as the influence of the coating process, powder moisture and the necessary heat treatment. It is known that a "high" powder humidity has a negative effect on the laser beam melting process and the resulting component properties. So far, no material-dependent value is known up to which powder can be processed reliably. There is also still a need for action with regard to the measuring method, especially for end users. Different methods are therefore being investigated in the project.

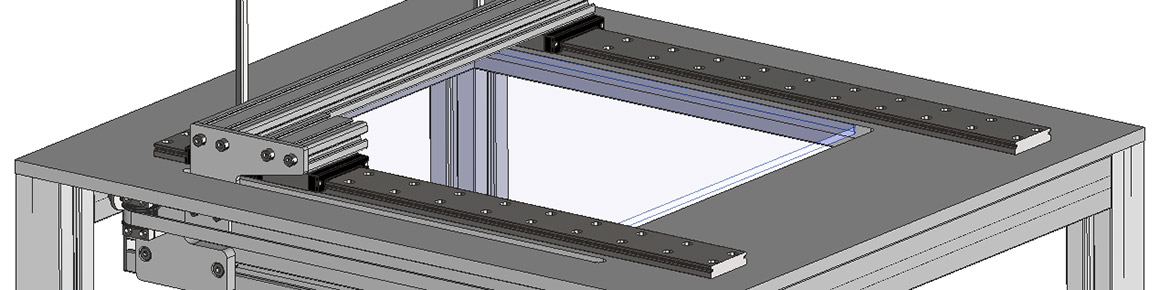

For the coating of the powder layer, the parameters to be investigated are the coating speed and the selection of the "levelling tool" (among others, coater lip or blade, geometry difference), which have an effect on the resulting powder bed. The heat treatment should first of all dissolve and homogenize the characteristic SLM microstructure and then optimize the mechanical properties with regard to an increase in toughness or yield strength.

- In summary, the following focal points are defined for the research project:

- Selection of suitable materials

- Optimization of the coating process

- Influence studies powder moisture

- Evaluation of the process parameters for the generation of thin-walled components

- Evaluation of a suitable heat treatment regime for setting flexible component properties

The material 1.4404 was initially specified for the material selection. Two further materials will be specified in the course of the project. The other materials are to be selected in such a way that the widest possible range of applications is achieved. Possible materials that can be selected on the basis of the potential application are

- Material 1.4828 (for applications at elevated temperatures >550 °C)

- Material 2.4856 (for applications under aggressive conditions, increased corrosion resistance)