AddLas

Förderkennzeichen: 49VF200044

Projektlaufzeit: 01.12.2020 bis 30.04.2023

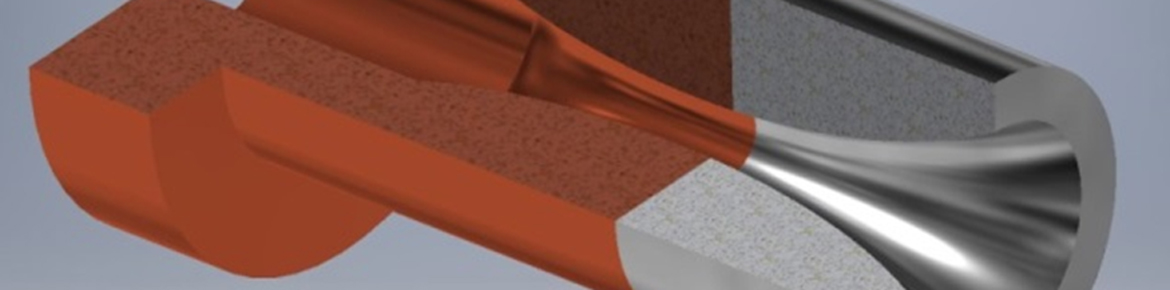

Additive manufacturing of multi-material parts

In the project, the advantages of additive processes are to be combined with those of material composites. The aim is to find a framework of possible material and process combinations for copper and steel mixtures and to determine the resulting advantages and disadvantages. A hybrid manufacturing process is used for this purpose in the project: conventionally manufactured semi-finished products are joined by laser welding to test specimens that were manufactured using material extrusion and powder bed processes. The hybrid manufactured parts will then be evaluated with regard to the quality of the mixed joints and the geometric accuracy that can be achieved. At the end of the project, a matrix is to be created that reflects recommended material combinations and enables application in an industrial environment.