PaSimAdd

Förderkennzeichen: 49VF210038

Projektlaufzeit: 01.12.2021 bis 31.05.2024

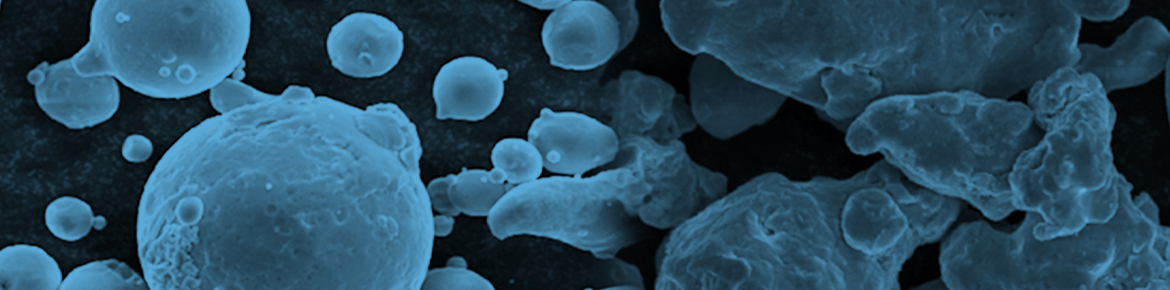

Particle simulation for additive manufacturing in powder bed

More and more companies are successfully using additive manufacturing processes. However, the reduction of current process costs is relevant for the further spread of these processes. The powder material is of particular importance here. Non-spherical particles are significantly faster and easier to produce than spherical powder particles. However, non-spherical powders cannot be applied homogeneously up to now.

Therefore, in this project, a deeper understanding of the behavior and interaction between individual powder particles will be developed. For this purpose, both experimental investigations and numerical simulations will be used. As a result, the process of powder bed-based manufacturing should become more robust: Findings on the behavior of the particles during coating application are to derive procedures for the use of non-spherical particles. In the project, ifw Jena will experimentally investigate powder application and carry out caft measurements, surface and particle measurements, while IAB will deal with numerical modeling and the development of new numerical approaches for the calculation of additive processes.

Therefore, in this project, a deeper understanding of the behavior and interaction between individual powder particles will be developed. For this purpose, both experimental investigations and numerical simulations will be used. As a result, the process of powder bed-based manufacturing should become more robust: Findings on the behavior of the particles during coating application are to derive procedures for the use of non-spherical particles. In the project, ifw Jena will experimentally investigate powder application and carry out caft measurements, surface and particle measurements, while IAB will deal with numerical modeling and the development of new numerical approaches for the calculation of additive processes.

Kooperationspartner: IAB – Institut für Angewandte Bauforschung Weimar gGmbH