Space-Alu

Förderkennzeichen: KK5130803AG1

Projektlaufzeit: 01.01.2022 bis 30.06.2024

Development of materials and parameters for manufacturing methods toDevelopment of materials and parameters for manufacturing methods to realize controlled CTE components for aerospace applicationsr Realization of controlled CTE components for aerospace applications

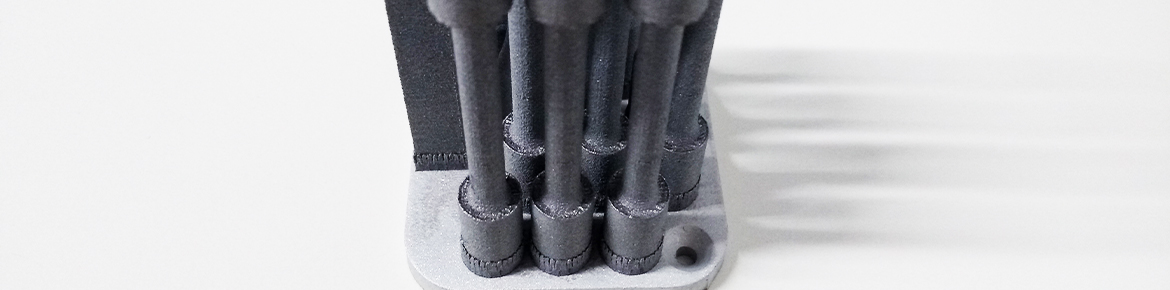

Sensors based on infrared technology are playing an increasingly important role in the construction of satellites. For applications in space, the mirrors used for infrared sensor technology must be able to withstand temperatures from -270 °C to 200 °C, have a good mass-to-strength ratio and surfaces with defined optical properties. A suitable material for these mirrors is aluminum alloy with high silicon content. The challenge in processing these materials is their high brittleness, which makes it difficult to produce complex shapes without high residual stresses.

The project will investigate how these materials can be optimally processed using powder bed-based methods to produce temperature-resistant mirrors with suitable surfaces for infrared technology on satellites. While the joint partner m4p is investigating the composition of the material, the processability of the powder into solid components is being studied at ifw Jena. The mirrors will be constructed and further processed after the construction process by the joint partner SPACEOPTIX. At the end of the project, there should be a process to reliably and efficiently manufacture these mirrors and make them available for space travel.

The project will investigate how these materials can be optimally processed using powder bed-based methods to produce temperature-resistant mirrors with suitable surfaces for infrared technology on satellites. While the joint partner m4p is investigating the composition of the material, the processability of the powder into solid components is being studied at ifw Jena. The mirrors will be constructed and further processed after the construction process by the joint partner SPACEOPTIX. At the end of the project, there should be a process to reliably and efficiently manufacture these mirrors and make them available for space travel.

Project partners: