Silent Cross

Förderkennzeichen: 49MF210201

Projektlaufzeit: 01.05.2022 bis 31.08.2024

Efficient crossjets by additive manufacturing

Aim of the Development

In laser beam welding, so-called crossjet nozzles are used to protect optics and protective glasses, most of which operate with compressed air. In addition to the relatively high compressed air consumption characteristic of these nozzles, they also generate noise emissions that have a lasting negative impact on working conditions. The aim of the project was to develop several energy-efficient crossjet nozzles that can be used to protect scanner optics from contamination such as welding spatter during laser material processing.

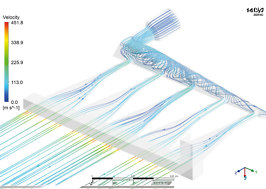

To achieve this goal, appropriately high flow velocities were required to generate sufficient momentum to deflect rising particles. Extensive preliminary investigations and comprehensive use of computer-aided simulation methods ensured that the necessary velocities were verified and achieved in subsequent developments. Another goal of the project was to keep noise emissions as low as possible and to reduce them compared to available nozzles. The target value was 60 dB. In addition, the developed nozzles were to be characterized by lower energy consumption, which is primarily generated by the provision of compressed air. The aim was to achieve improvements of approx. 25% compared to conventional crossjet nozzles.

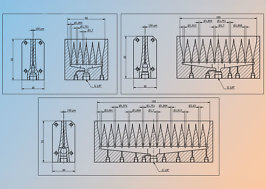

As a result, three nozzles with widths of 50 mm, 100 mm, and 150 mm were developed and tested, enabling scanner optics of different sizes to be protected efficiently and quietly. In terms of the processing area, these nozzles save up to 83.3% compressed air compared to conventional crossjets. Furthermore, the noise level of the 50 mm wide nozzle was reduced to below 60 dB(A). This provides users with a nozzle set that can be optimally used for the corresponding process.

Advantages and Solutions

The approach to minimizing the volume flow and noise emissions was based on the flow-optimized geometry of the nozzles. A uniform velocity across the flow field increases efficiency and thus the compressed air consumption of the nozzles. Reduced turbulence in the free jet of the flow also leads to a lower noise level. The concrete implementation of the optimization was based on the design advantages of powder bed-based additive manufacturing with laser beams (PBF-LB). This manufacturing process allows geometries to be realized that would not be possible with conventional methods. Due to the low layer build-up of the powder, the design freedom is limited almost exclusively by internal support structures that cannot be removed afterwards. Therefore, flow-optimized geometries can be produced using this process. The flow optimization itself was carried out numerically using CFD simulations and based on the findings obtained from the downstream PIV measurements. Together with the design, this flow optimization represented a development loop through which the nozzle generation was gradually finalized.

The final welding test of all newly developed Crossjet nozzles proved their functionality and efficiency in terms of volume flow and noise emission. The project was divided into different project phases and intermediate goals:

- Creation of boundary conditions and comparability for nozzle development

- Preliminary investigation of effective flow cross-sections

- Development and optimization loop for the final nozzle design

- Proof of functionality and effectiveness

Target Market

The fundamental advantages of laser and laser remote welding include precise energy input and the associated ease of integration into automated welding systems, as well as high welding speeds and the associated lower welding costs. Due to these advantages, the main industries for laser welding are the automotive and electrical industries, as well as medical technology. An essential task, especially in remote laser welding, is the reliable protection of expensive welding optics from rising welding spatter, for which Crossjet nozzles are used. The implemented project therefore affects both system manufacturers and process users. The users of the processes are predominantly small and medium-sized enterprises. The implemented project offers these target groups great savings potential to increase and secure their competitiveness in the long term. The low noise emission of the newly developed Crossjet nozzles also improves working conditions, which is a reason for integration into existing systems that should not be underestimated. On the user side, the developed nozzles have already attracted considerable interest. This attention was generated primarily through various educational events. The Crossjet nozzles are also already in widespread use in-house at ifw Jena.