DruSint-AM

Förderkennzeichen: KK5130805IE3

Projektlaufzeit: 01.03.2024 bis 28.02.2027

Development of an optimized pressure-sinter route for sinter-based additive manufacturing

Sinter-based additive processes for metallic materials offer great potential for cost-effective prototype and series production. However, the necessary post-treatment, consisting of debinding and sintering, regularly leads to component densities of 95 to 98%, which limits the usability of the components. In order to achieve higher densities for high-performance applications, post-compaction by hot-isolation pressing is required.

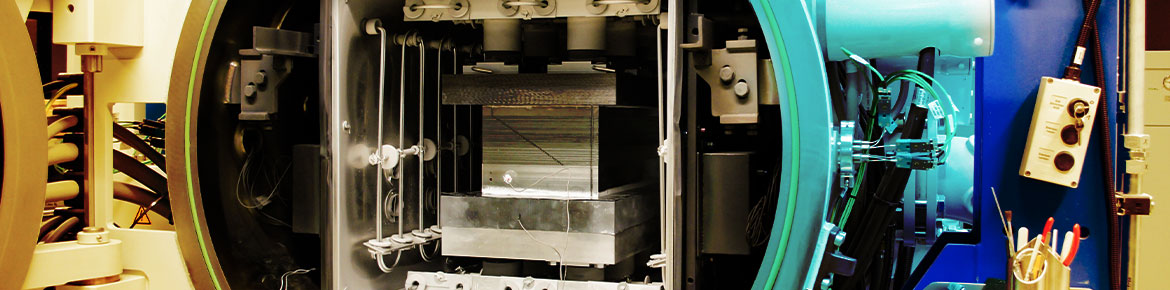

Pressure sintering can be a more cost-effective way of improving component quality. However, this process is not yet qualified for materials such as stainless steels, titanium alloys or Inconel. The aim of the project is therefore to develop a pressure sintering route for additive manufacturing processes together with the joint partners in order to realize high-performing components within a combined heat treatment consisting of debinding, sintering and post-compaction.

The ifw Jena is working on the sub-project "Development of strategies for pressure sintering with reduced working pressure".

working pressure."

Pressure sintering can be a more cost-effective way of improving component quality. However, this process is not yet qualified for materials such as stainless steels, titanium alloys or Inconel. The aim of the project is therefore to develop a pressure sintering route for additive manufacturing processes together with the joint partners in order to realize high-performing components within a combined heat treatment consisting of debinding, sintering and post-compaction.

The ifw Jena is working on the sub-project "Development of strategies for pressure sintering with reduced working pressure".

working pressure."

Verbundpartner: