EVP

Förderkennzeichen: 2023 VDY 0018

Projektlaufzeit: 01.05.2024 bis 30.04.2025

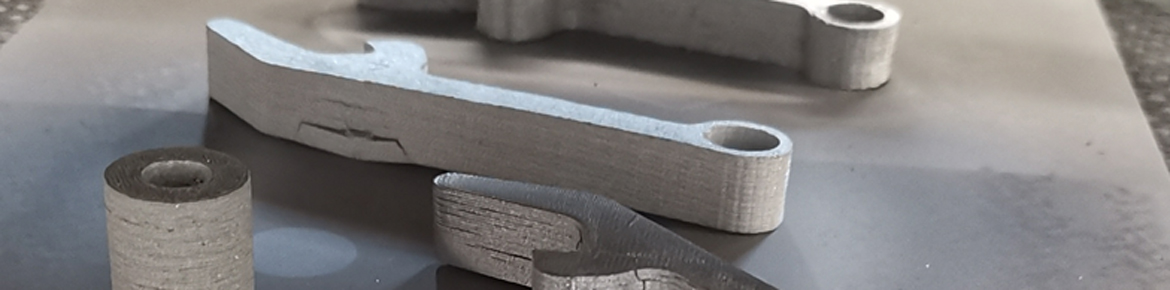

Development of a validated process chain for manufacturing of metal prototypes by means of material extrusion

Compared to powder bed processes, sinter-based additive processes cause significantly lower costs and have a high scaling potential due to low system costs. The process has been standard for plastics processing for years and has also become more important for metals in recent years. The project addresses current obstacles with regard to design, debinding, sintering and post-processing. A conversion of "plastic printers" for the processing of metal-filled filaments is also being investigated. The main objective of the project is to develop a validated process chain for the production of metallic functional prototypes using material extrusion. Previous findings of ifw Jena on the material extrusion of metallic materials are applied to typical geometries of the company PORTEC. It is essential to analyze the PORTEC product portfolio and to transfer scientific investigations to these geometries.

Partner: PORTEC GmbH