Rebond

Förderkennzeichen: 49MF220044

Projektlaufzeit: 01.09.2022 bis 31.07.2024

Qualification of recycled plastics for adhesively bonded joints

Aim of the development

Plastics are an elementary part of our lives and are used, for example, in the mobility sector, in the electronics and entertainment industry and in numerous consumer goods. Due to their simple and inexpensive availability, ease of processing and low weight, plastics are being used in an increasingly wide range of applications, which is reflected in a steady increase in plastic production. However, many plastic products are disposable, meaning that many products represent an environmental burden at the end of their product life. In order to reduce the input of plastics into the environment, for example, the transformation from a linear to a circular plastics economy must be completed.

Politically, this transformation pressure is based on Directive 2008/98/EC (Waste Framework Directive), the Act to Promote the Circular Economy and Ensure the Environmentally Sound Management of Waste (Circular Economy Act) and the European Circular Economy Act. The aim of these directives and laws is to reduce the consumption of fossil raw materials and thus the destruction of habitats during their extraction as well as the greenhouse gas emissions resulting from their production. The EU Packaging and Packaging Waste Directive (Directive EU 2018/852), which was amended in 2018, also stipulates binding recycling quotas. For example, 50% by weight of plastic packaging waste must be recycled by 31.12.2025 and 55% by weight by 31.12.2030. The Rebond project should qualify recycled plastics for subsequent applications and reduce reservations about the quality of recycled materials.

Advantages and Solutions

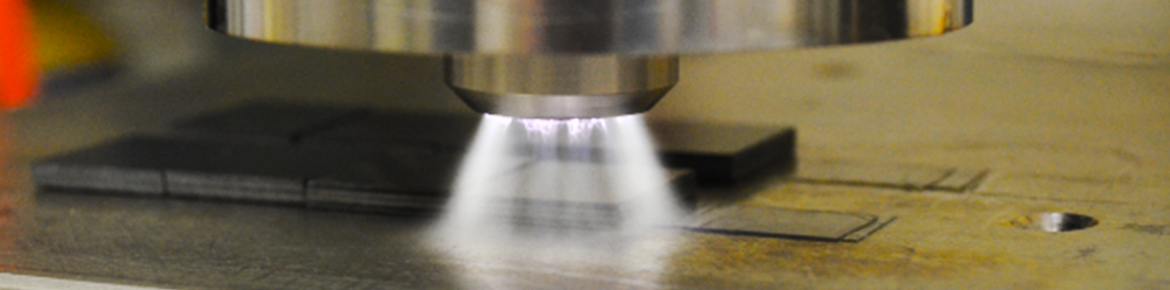

Within the project, the two plastics polyethylene terephthalate (PET) and acrylonitrile butadiene styrene copolymer (ABS) with a recycled content of 0 %, 80 % and 100 % were examined comparatively. For this purpose, the virgin material and the plastics with recyclate content were examined for their characteristic values of average roughness, impurity content, tensile strength, thermal linear expansion, water absorption and surface energy. In addition, the various plastic mixtures were bonded together using different types of adhesive (polyurethane, methacrylate, hotmelt). The bonded samples were subjected to a compression shear test to determine the strength of the bond. The bonded samples were then subjected to climate storage, which simulates the ageing of the bonded joint, allowing conclusions to be drawn about the bond strength due to long-term environmental influences. The aged samples were also examined using the pressure shear test and compared with the unaged samples.

Overall, this project was able to show that the PET and ABS plastic recyclates in the tests conducted at ifw Jena have the same or only slightly different properties compared to primary plastics, both in terms of material properties and adhesive strength, which makes them interesting materials in terms of possible CO2 savings. This may encourage small and medium-sized companies in the plastics processing sector to make greater use of recycled plastics in the future.

Target Market

The results of the project are aimed at all plastics processing companies, as they will have to deal with the use of recyclates in the foreseeable future. However, the results achieved are primarily aimed at SMEs, which do not have the opportunity to carry out their own research into the suitability of recycled plastics. The transfer of knowledge mainly takes place via the publication of project results at conferences or in specialist journals. In the case of LOI donors, the results are made available as a report. Due to the politically desired transformation to a circular economy and the binding recycling quotas, an increase in inquiries from industry on the subject of recycled plastics is expected in the coming years. The experience gained in this project is expected to lead to industry-related research/research projects.