Nanogel

Förderkennzeichen: 49VF240017

Projektlaufzeit: 01.09.2024 bis 30.11.2026

Nanogel

Nanoparticles have unique properties that are not found in macroscopic solids. Due to these special properties, they offer the potential to develop more efficient manufacturing methods in many different areas. For example, metallic nanoparticles as solder materials can enable a reduction of the melting point by several 100 degrees Celsius due to an increased surface-to-volume ratio.

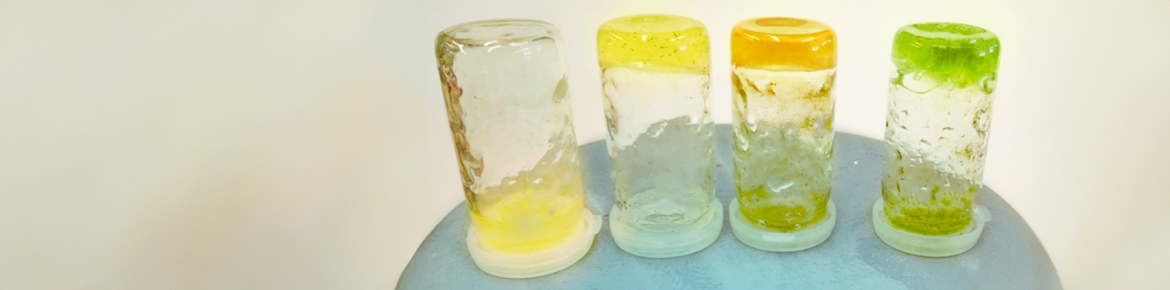

The project will investigate two ways of obtaining nanoparticles: Ultrashort pulse laser ablation in solution and wet chemical synthesis. However, the nanoparticles are not to be obtained in pure form, i.e. as a powder, but bound in an organic gelling agent. These nanoparticle gels will then be evaluated with regard to their suitability for soldering processes. The influence of the gel matrix or how it can be removed in oven-bonded soldering processes will be investigated. Joining samples will be produced and tested for their strength properties.

At the end of the project, the nanoparticle gels are expected to create a new form of application for industrial soldering processes that will enable companies to carry out soldering processes in a more energy-efficient and therefore more economical way thanks to the lower melting points of the nanoparticle solders.

The project will investigate two ways of obtaining nanoparticles: Ultrashort pulse laser ablation in solution and wet chemical synthesis. However, the nanoparticles are not to be obtained in pure form, i.e. as a powder, but bound in an organic gelling agent. These nanoparticle gels will then be evaluated with regard to their suitability for soldering processes. The influence of the gel matrix or how it can be removed in oven-bonded soldering processes will be investigated. Joining samples will be produced and tested for their strength properties.

At the end of the project, the nanoparticle gels are expected to create a new form of application for industrial soldering processes that will enable companies to carry out soldering processes in a more energy-efficient and therefore more economical way thanks to the lower melting points of the nanoparticle solders.