RapidMLA

Förderkennzeichen: ZF4236511BA9

Projektlaufzeit: 01.04.2020 bis 31.07.2022

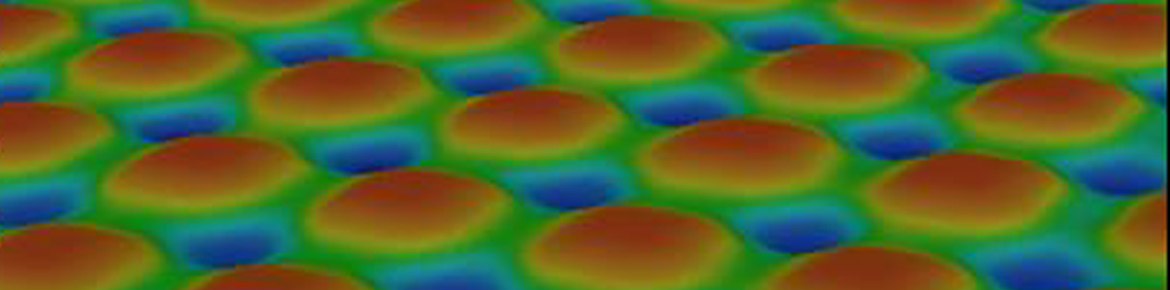

Fast direct fabrication of microlens arrays and freeform optics by CO₂ laser ablation and polishing – Subproject: Development of the ablation and polishing process for microlens arrays and freeform optics.

There are currently few economical methods for fabricating free-form optics (especially microlens arrays) from glass. Individual elements can indeed be fabricated by photolithography and ion beam etching. However, this requires masks, which have a unit-independent cost per design, and is relatively slow for structures deeper than a few micrometers. The goal of the project is therefore to develop rapid direct fabrication of microlens arrays and free-form optics by CO2 laser ablation and polishing. The laser is the ideal tool for this purpose, since it enables wear-free, reproducible ablation as well as extensive automation and digital integration. The planned process development makes it conceivable to build a laser system that requires only substrate material and geometry data sets and uses them to automatically manufacture and measure individual pieces with short cycle times.

Project partner: Präzisionsoptik Gera GmbH