LAMENT

Förderkennzeichen: 01IF22186N

Projektlaufzeit: 01.05.2022 bis 30.04.2024

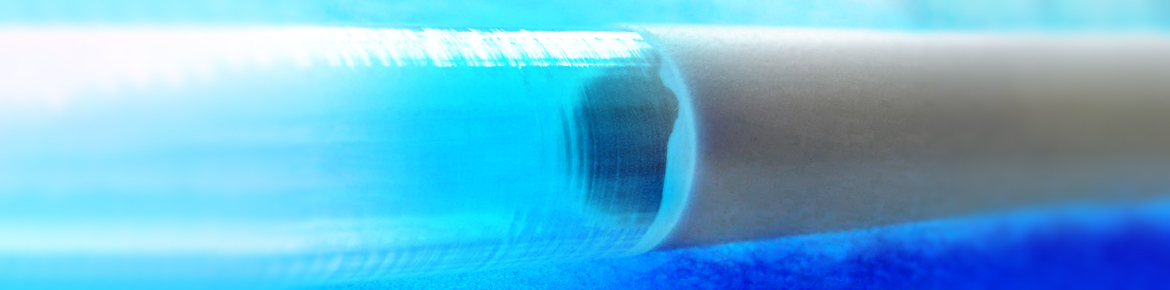

Development of local brazing of rotational symmetric multi-material concepts

The brazing of metal-ceramic or ceramic-ceramic composites as a multi-stage process chain in the furnace is state of the art. The disadvantages of these processes are their high time requirements and the high overall heat load on the assembly.

The aim of the project is to develop a process control system for local soldering of multi-material composite modules made of high-performance ceramic materials and metal. The process control to be developed is to be carried out locally on the component and adapted to the material and function. For this purpose, it will be investigated which parameters influence the laser soldering process of metal, active and glass solders. Based on these findings, a local laser and induction brazing process will then be developed. By introducing energy locally directly in the joining zone, components can be produced more efficiently.

The process enables an increase in component quality as well as new freedoms in design and material selection, allowing companies to expand their products and offer them in a more customized way.

While the laser brazing process is being investigated at ifw Jena, the project partner Fraunhofer IKTS is taking on the tasks of selecting and characterizing the brazing base materials.

The aim of the project is to develop a process control system for local soldering of multi-material composite modules made of high-performance ceramic materials and metal. The process control to be developed is to be carried out locally on the component and adapted to the material and function. For this purpose, it will be investigated which parameters influence the laser soldering process of metal, active and glass solders. Based on these findings, a local laser and induction brazing process will then be developed. By introducing energy locally directly in the joining zone, components can be produced more efficiently.

The process enables an increase in component quality as well as new freedoms in design and material selection, allowing companies to expand their products and offer them in a more customized way.

While the laser brazing process is being investigated at ifw Jena, the project partner Fraunhofer IKTS is taking on the tasks of selecting and characterizing the brazing base materials.

Project partner: Fraunhofer-Institut für Keramische Technologien und Systeme IKTS, Hermsdorf