TemGro

Förderkennzeichen: 2016 FGR 0035

Projektlaufzeit: 01.10.2016 bis 30.09.2019

Tempered large tools

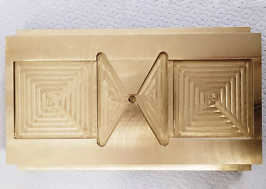

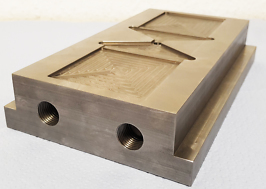

The approach of the "TemGro" research-group is to develop additive manunfacturing processes, especially forming arc welding and diffusion bonding, so forming tools can be produced with larger integrated structures to control temperatures. The potentials of both welding processes for the production of geometrically large moulds with complex cooling channel structures will be investigated and functional models will be developed.

The research group project "TemGro" will be carried out by the University of Applied Sciences Schmalkalden (materials/construction), Technical University Ilmenau (arc welding) and ifw Jena (diffusion bonding) according to their competences and main topics.

A forming tool with cooling channel structures was constructively developed. A material-specific selection was made with regard to the functional tool properties, availability and machinability.

Further considerations are the process-technical parameter qualifications for additive production and reproducibility as well as material-technical investigations for welding and composite formation.

Supported by the Free State of Thuringia with funds from the European Social Fund.