TLP-Bonding

Förderkennzeichen: 49MF220157

Projektlaufzeit: 01.01.2023 bis 31.12.2024

Bonding of machining steel and titanium by means of TLPB

Development objective

The objective of the research project was to develop new manufacturing approaches for joining technology that combine the advantages of diffusion welding and soldering in a hybrid process. This is based on transient liquid phase bonding (TLP bonding), in which low-melting metallic foils are used to achieve a material bond between two joining partners.

TLP bonding is a low-temperature metal joining technique that combines the mechanical stability and conductivity of metal joints with comparatively low process temperatures. This is made possible by the formation of temperature-resistant alloys during the process through diffusion between a low-melting and a high-melting phase. One example of this is the silver (Ag) and tin (Sn) system, in which a joint can be produced at a process temperature of 250 °C that remains thermally stable at temperatures above 400 °C.

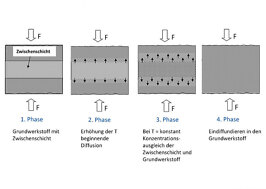

The project aimed to investigate whether the TLP process can be transferred to material systems that require higher operating temperatures, for example above 900 °C. The aim is to contribute to expanding the industrial application spectrum of TLP bonding. A key advantage of the TLP process is that the required joining temperature – similar to brazing – is significantly lower than that of diffusion welding. This reduces the risk of undesirable microstructural changes. At defined temperatures and under surface pressure, the intermediate layer between the joining partners forms a partial melt, which ideally diffuses into the base material without reactions that form brittle phases. The driving physical force is diffusion, which is supported by the applied pressure, thus enabling a connection at lower temperatures. The central sub-goals of the research project were:

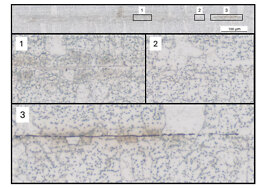

- Production of a material-locked joint with a homogeneous and low-stress metallic interlayer

- Material characterisation of the joining zones with regard to homogeneity, porosity and crack formation – Investigation of the diffusion and phase formation processes between the interlayer and the base material

- Prevention of undesirable structural changes (e.g. coarse grain formation) during the joining process

- Significant reduction in joining temperature compared to diffusion welding

- Minimisation of distortion and compression through targeted adjustment of the pressing force

- Analysis of scaling effects depending on component size and applied surface pressure

- Development of a reproducible process concept with regard to material selection, surface quality and process control

- Ensuring sufficient thermal and mechanical properties of the manufactured joints for subsequent applications

Advantages and solutions

In order to develop a reliable and, at the same time, material-friendly joining technology for high-temperature applications, transient liquid phase bonding (TLPB) was investigated as a central solution approach. This process specifically combines the advantages of diffusion welding and soldering, thus offering an approach that is both energy-efficient and resource-saving. Diffusion welding has become particularly established for large-area, material-locking joints, but requires very high temperatures and pressing forces. These extreme process conditions lead to several disadvantages: The entire component is subjected to severe thermal stress, which leads to undesirable structural changes in many materials, such as titanium or steel alloys.

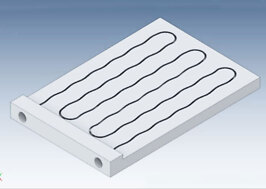

With titanium, such as the TiAl6V4 alloy, diffusion welding requires temperatures above the transition temperature, which causes phase transformations and changes the mechanical properties of the material. In steels, coarse grain formation occurs, which impairs strength. In addition, the high pressing pressure required causes deformation of the component, which is particularly problematic for components with flow-relevant structures. These effects make it difficult to accurately predict the compression and often require subsequent heat treatments. As an alternative technology, brazing offers lower process temperatures and completely eliminates the need for high external pressing forces. However, this often results in brittle and mechanically weak phases in the brazed joint. In titanium in particular, the reaction between the brazing material and the base material leads to the formation of boron- or phosphorus-containing intermetallic phases, which significantly reduce corrosion resistance, service life and fatigue strength. The lower strength of the brazed joint remains a significant limiting factor, even though the process offers advantages in terms of deformation for components with high dimensional accuracy requirements, such as tool steel components in the hot runner area. The TLPB process is a technically sound solution that combines the strengths of both processes while minimising their disadvantages.

By using low-melting, pure metal foils such as tin or aluminium, a thin intermediate layer is introduced between the joining partners, which initially forms a short-term melting phase at moderate temperatures. The components of this melting phase then diffuse into the base material in a controlled manner. This extended diffusion time ideally results in a uniform mixed crystal structure throughout the entire joining zone. The resulting joint is more temperature-resistant and mechanically resilient than a classic soldered joint, without the high thermal stresses of diffusion welding. The additional application of moderate pressure – significantly lower than in diffusion welding – accelerates these diffusion processes and enables a low-stress connection with minimal component deformation. Since purely metallic foils are used, the formation of undesirable brittle phases is greatly reduced, and the resulting phases are more predictable than with complex solders.

This allows the creation of a joining zone whose strength and temperature resistance exceed the properties of the film material used and approximate those of the base material. TLPB thus offers a viable approach to producing stable, homogeneous and high-temperature-resistant joints under significantly reduced process conditions, thereby delivering both technical and economic advantages.

Target market

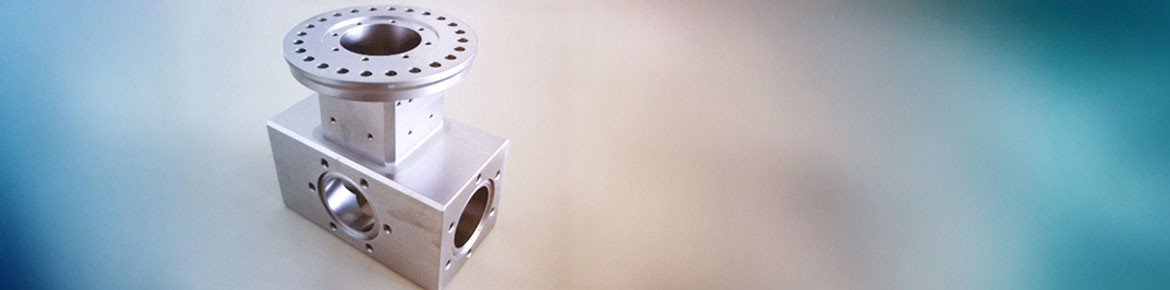

The TLPB joining technology developed in the project is aimed at national and international industrial sectors that require high-temperature-resistant, mechanically resilient and dimensionally stable joints. The main target groups include companies in the aerospace, energy and plant engineering, automotive, tool and mould making industries, as well as small and medium-sized enterprises (SMEs) in particular, which manufacture tool inserts, hot runner systems and other complex metal assemblies, for example. These industries benefit particularly from joining technologies that are both reliable and resource-efficient. A particular advantage of the process lies in the reliable and fixture-free joining of titanium alloys and tool steels, which was previously technically demanding and cost-intensive, mainly due to high process parameters.

The use of low-melting pure metal intermediate layers and a comparatively simple surface pretreatment process significantly reduces energy-intensive process variables such as temperature, holding time and the required pressing force. This not only leads to direct cost savings, but also improves the suitability of the process for series production: with reduced pressing force, for example, this can be applied using simple weights, eliminating the need for external pressing devices. In this way, a larger number of components – even those with different geometries – can be manufactured in a single process run. At the same time, the thermal load on the entire component is significantly reduced. This largely prevents undesirable structural changes such as coarse grain formation or phase transformations, thus preserving the original material properties. Additional heat treatments for structural restoration become unnecessary, further increasing the economic benefits.

Furthermore, the use of cost-effective pure metal foils opens up new applications for products whose manufacture was previously not economically viable due to expensive, complex solder compositions. The results of the project are relevant both scientifically and technically as well as economically. The expansion of the process window to lower temperatures, new insights into the diffusion behaviour between substrates and pure metals, and the influence of surface pretreatment provide important impetus for research and industrial application. Economically, the industry benefits from significant energy savings, reduced process times and lower costs for the pre- and post-processing of joints. Although the mechanical characteristics achieved in the project – particularly with regard to shear strength – did not yet reach the level of industrially established joining processes in all cases, relevant structural strengths were nevertheless demonstrated, confirming the fundamental potential of single-component TLP joining. Especially with longer holding times, seam formation and phase homogeneity improved significantly, which had a positive effect on the strength and stability of the joints.

These results show that the process – with optimised process control and suitable material combinations – has the potential to provide reliable and temperature-resistant joints in the future. For applications with moderate mechanical requirements or for components that are subject to high thermal loads but less mechanical stress, single-component TLP joining is already a promising technological option. The transfer of R&D results takes place directly in cooperation with user companies. Thanks to the research institution's existing expertise, this transfer extends from feasibility studies to prototype production and small-batch production. In addition, consulting services and technology training are offered to support the transfer of the process into industrial manufacturing processes.

This creates sustainable economic potential and new fields of application for both the companies and the research institution, which are to be transferred beyond the project to other material systems and industries.