KerKoWas

Förderkennzeichen: 01IF00072L

Projektlaufzeit: 01.11.2023 bis 30.04.2026

Diffusion bonded ceramic sheet-joints with high thermal shock resistance

As part of the overall project "Development of innovative energy efficiency strategies based on novel and additively manufactured ceramic hydrogen burner components", ifw Jena, together with Fraunhofer-IKTS and TU Dresden, is working on ways to additively manufacture ceramic hydrogen burner components economically. The aim of the project is to provide ceramic components for hydrogen burner technology. These innovative components should significantly improve the existing technology in terms of resource use, reliability and operating behavior. In addition, the energy efficiency should be at least equivalent to the state of the art.

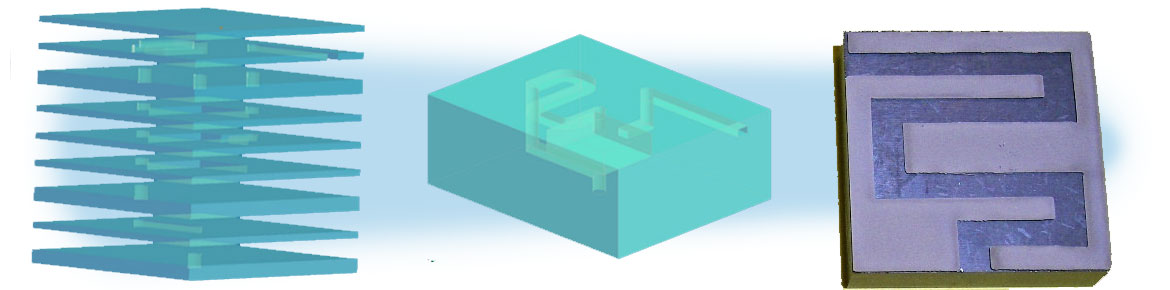

Ceramic materials are characterized by high thermal stability and corrosion resistance at very high temperatures. The production of such a material composite is not possible using conventional powder-based sintering processes. One way of creating the desired composite is by diffusion bonding ceramic films. The project aims to develop the basic technological knowledge for the production of burner components for hydrogen combustion by diffusion bonding ceramic foils and the knowledge for adapting the material properties for foil composites.

Ceramic materials are characterized by high thermal stability and corrosion resistance at very high temperatures. The production of such a material composite is not possible using conventional powder-based sintering processes. One way of creating the desired composite is by diffusion bonding ceramic films. The project aims to develop the basic technological knowledge for the production of burner components for hydrogen combustion by diffusion bonding ceramic foils and the knowledge for adapting the material properties for foil composites.

Project partners: