ROfl

Förderkennzeichen: MF150221

Projektlaufzeit: 01.05.2016 bis 30.04.2018

Reduction of surface roughness of laser beam melted components

The aim of the research project is to characterize the 3D surfaces typical for selective laser beam melting and to qualify methods for the reduction of roughness. The focus is on the qualification of beam-technical, chemical and electrochemical ablation processes for improving the surface and its correlation to technological and mechanical properties of the generated components. On the basis of these investigations, the previously costly post-processing of beam melted components with conventional machining processes can be reduced and thus the economic efficiency of the process can be increased.

For this purpose, a correlation of the achieved surfaces with the respective mechanical properties is indispensable, since the surface roughness has a significant influence on the component strength. For the successful processing of the research project the following main focuses are defined:

- Adjustment of the laser beam melting process to reduce the amount of post-processing

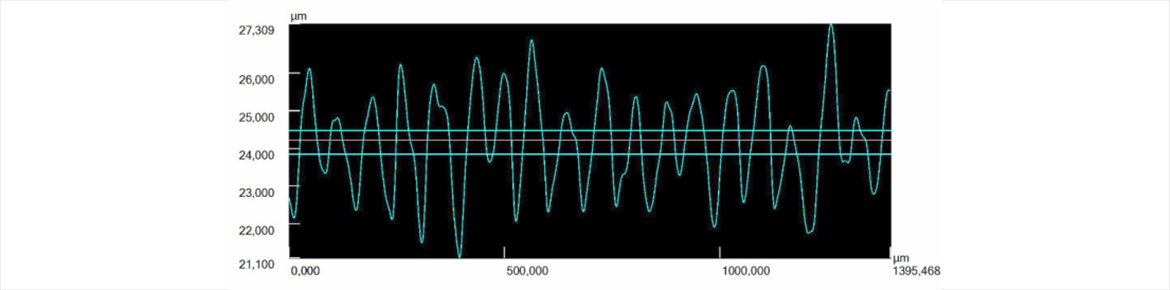

- Determination of surface roughness (S-parameter and R-parameter) and correlation to mechanical properties

- Evaluation and optimization of suitable processes for the reduction of surface roughness

- Evaluation of the costs of the respective surface treatments and comparison with conventional processes