AluQua

Förderkennzeichen: 01IF22314N

Projektlaufzeit: 01.06.2022 bis 31.05.2024

Quality assurcance of powder and component properties in the PBF-LB-process für aluminum alloys

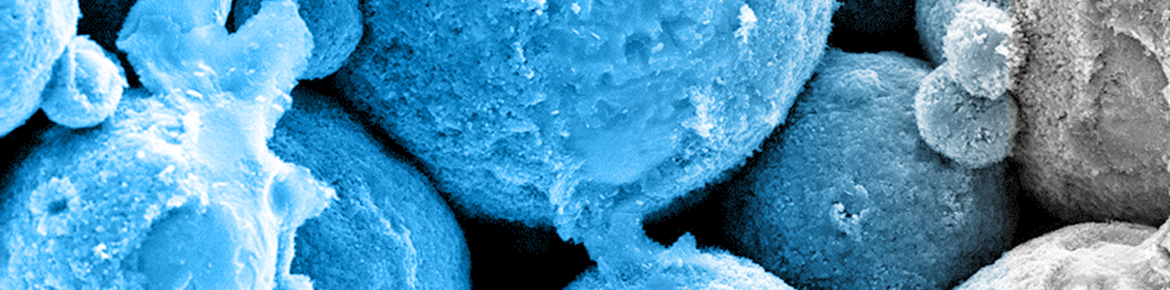

In addition to the many advantages that powder bed-based additive manufacturing processes offer for industrial applications, they also have potential for improvement, particularly with regard to the quality fidelity of the components. One main reason is the powder used and its handling. Aluminum powders in particular have a high affinity for absorbing surface moisture. General powder handling is also challenging with aluminum powders.

In the research project, measures are to be developed to improve quality assurance and the handling of aluminum powders. As a result, measurement methods for powder moisture determination will be evaluated and a rapid test adapted for industrial use. The powder certificate quality and the suitability of the measurement methods used will also be evaluated. In addition, new insights into the powder aging process and work instructions for efficient screening of used powder will be generated. With these findings, it can be made easier for companies to introduce additive processes. As a result of improved quality assurance and thus increased component quality, not only increased customer satisfaction but also a reduction in material expenses as well as defect and follow-up costs could be achieved.

In the research project, measures are to be developed to improve quality assurance and the handling of aluminum powders. As a result, measurement methods for powder moisture determination will be evaluated and a rapid test adapted for industrial use. The powder certificate quality and the suitability of the measurement methods used will also be evaluated. In addition, new insights into the powder aging process and work instructions for efficient screening of used powder will be generated. With these findings, it can be made easier for companies to introduce additive processes. As a result of improved quality assurance and thus increased component quality, not only increased customer satisfaction but also a reduction in material expenses as well as defect and follow-up costs could be achieved.

Project partner: Fraunhofer-Einrichtung für Additive Produktionstechnologie IAPT