DeepX

Förderkennzeichen: 49MF210091

Projektlaufzeit: 01.11.2021 bis 30.04.2024

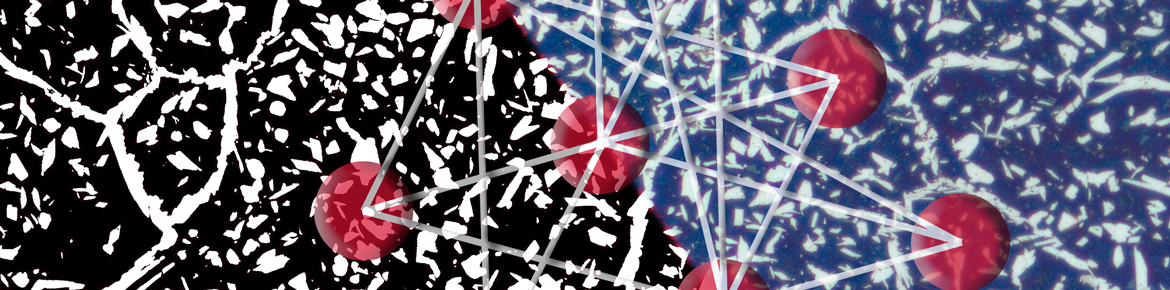

Deep learning for metallography of duplex steel

In the project, various advanced image processing methods are to be applied, tested and compared in order to create the basis for automating these methods. A system will be developed to demonstrate an end-to-end automated process from the acquisition of one or more images to the output of results.

Against the background of current industrial challenges, the work will focus primarily on low-alloy lightweight steels, especially duplex steels, and their welded joints.

In metallography, micrographs are evaluated, for example, to determine phase fractions and to characterize the phases. Digital image processing methods are increasingly being used for this purpose. However, complex visual support is often still required. The micrographs often have irregular structures and the individual phase components are difficult to distinguish from one another using purely algorithmic methods. At ifw Jena, work is therefore being carried out to make the evaluation of digital micrographs more effective by means of "learning methods".

In the project "DeepX - Deep learning for the metallography of duplex steels", learning methods are being tested on selected samples to enable automated determination of the phase fractions of duplex steels. Deeply structured neural networks will be used in particular. These are first trained with a large number of images, image sections or image features. The learning success is checked and improved by adjusting selected parameters. After successful learning, the trained networks can then be used for fully automated quality inspection. In addition to duplex steels, the scope of application will later be extended to other steel grades and other materials such as ceramics.

For metallographic materials testing, the use of deep learning software offers great advantages. The purely visual evaluation of a single micrograph usually takes several minutes. Individual grain areas have to be delineated from one another and their size and phase affiliation checked. Software-based algorithmic methods are significantly faster, but because of the irregular structures of the micrographs, they often still require interactive intervention by the user, which still takes a lot of time, especially when evaluating a large number of images. Learning methods, on the other hand, allow a more reliable evaluation even without interactive intervention and can thus be fully automated. These methods offer considerable advantages, especially when evaluating several hundred micrographs, for example.

With this project, companies can greatly optimize the quality assurance of metallographic samples. The automated and reliable evaluation of several micrographs in the shortest possible time saves personnel and time resources that were previously tied up in quality assurance processes.