KLasBau

Förderkennzeichen: MF150198

Projektlaufzeit: 01.04.2016 bis 31.03.2018

Investigation/optimization of the adhesive suitability of components manufactured by laser beam melting for lightweight construction

The aim of the project is to investigate the adhesive joining of SLM (Selective Laser Melting) manufactured components made of AlSi10Mg and TiAl6V4 with other materials for lightweight construction. In addition to the evaluation of the generatively manufactured surfaces, these are also to be specifically optimised in order to improve the adhesive properties. In order to be able to prove the usability of the bonded components, ageing tests are carried out. In particular, application-related thermal loads of lightweight construction in the low and high temperature range are investigated.

The following approach was defined for the successful processing of the research project:

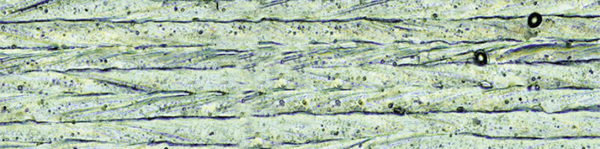

- Characterization/examination of the adhesive suitability of SLM-produced surfaces

- Bonding surface conditioning of SLM-generated surfaces in the SLM manufacturing process and/or by surface pretreatment

- Production of bonded material connections for applications in the low temperature range, for applications up to 300 °C and for applications in the high temperature range

- Performance of application-oriented load tests in the temperature ranges mentioned

- Testing of selected material combinations under real operating conditions