KoLaDu

Förderkennzeichen: 01IF20721N

Projektlaufzeit: 01.05.2019 bis 31.08.2022

Corrosion mechanics at laser welding of duplex steel

Action

In order to illustrate the sub-areas of laser and materials technology, an interdisciplinary working method in a network (Institute for Corrosion Protection Dresden GmbH and the Günter Köhler Institute for Joining Technology and Materials Testing GmbH) is necessary.

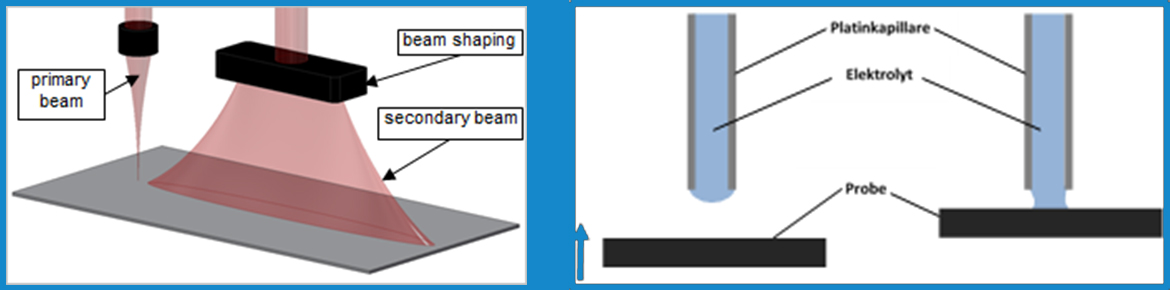

With the help of beam-forming elements, an asymmetrical beam and intensity profile is to be generated, whereby a material-specific temperature field is created. In order to achieve an adapted process control, the investigations are extended by the temporal variation of the energy input and the protective gas composition. For electrochemical corrosion testing of local damage (such as in the weld area), large-scale measurements alone are often unsuitable. Investigations in the micro or macro area are indispensable for the determination of corrosion. Therefore, the development of a microelectrochemical measuring cell to determine the corrosion resistance of the weld is necessary.

The project focuses on the scientifically proven development of a process strategy for the welding of thin-walled duplex structures without the use of additional material or a subsequent work step. In addition, companies will be able to use a suitable measuring technique to check the weld seams on site, nondestructive or destructive, immediately after the welding process. For the user, this means an efficient design of the process.

Results

The project was successfully completed. It was possible to form reheat profiles with a second laser beam, which significantly increase the corrosion resistance of the weld seam so that it has the same resistance as the base material. In addition, the IKS developed a microelectrochemical measuring cell that can measure the corrosion resistance of the weld seam without also measuring the surrounding base metal. This drastically increases the accuracy of the measurement and enables non-destructive seam testing directly after the welding process. The complete project results will soon be available from the Forschungsvereinigung Stahlanwendung e. V. (Research Association for Steel Applications).

Partners

Accompanying committee

- Agnilaser GmbH

- Bank Elektronik-Intelligent Controls GmbH

- DKI GmbH

- DSI Laser Service GmbH

- GASKATEL Gesellschaft für Gassysteme

- IBS Anlagen + Montage GmbH

- Industrie Montage-Service Ichtershausen

- JENOPTIK Automatisierungstechnik GmbH

- Laservorm GmbH

- Laserzentrum Schorcht GmbH

- LINDE AG

- Outokumpu

- PSL Technik GmbH

- SCHERDEL GmbH

- Vallourec Deutschland GmbH

- Wilhelm Modersohn GmbH & Co. KG

The IGF project "Corrosion mechanisms in laser welding of duplex steels (KoLaDu)", IGF project no. 20721 BR, of the Forschungsvereinigung Stahlanwendung e. V. (FOSTA), Sohnstraße 65, 40237 Düsseldorf, Germany, was funded by the German Federal Ministry of Economics and Climate Protection via the AiF as part of the program for the promotion of joint industrial research (IGF) on the basis of a resolution of the German Bundestag.