MuBeGla

Förderkennzeichen: 49MF200063

Projektlaufzeit: 01.10.2020 bis 28.02.2023

Fast glass welding with ultra short pulse lasers

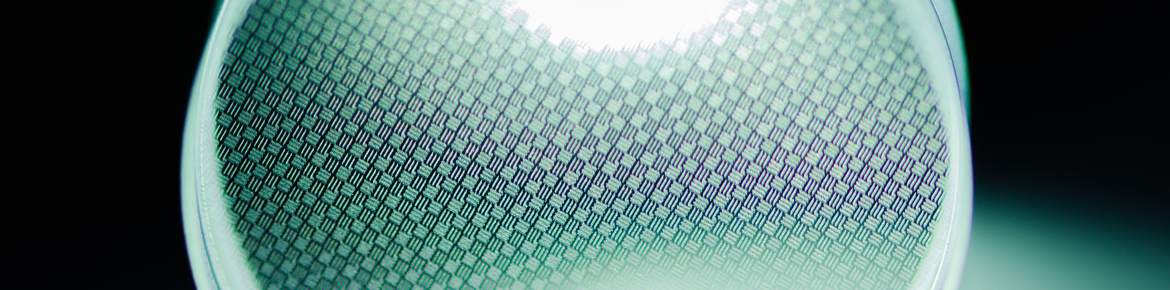

Industrial joining of glass is a challenge even with the most modern technology. If the joining zone is to have the same properties as the surrounding glass, classical joining methods are not applicable. The project therefore aims to further investigate local glass welding with ultrashort pulse lasers (UKP). This process is based on a spatially very limited energy input, which produces melting zones of about 100 μm diameter. Since the process works through the transparent glass, interfaces that are not mechanically accessible are weldable in the process. In the "UKP Glass" project (49VF170036), it was demonstrated at ifw Jena that joints are also possible without optical contacts. However, one hurdle in UKP glass welding is still the process speed, which is crucial for the economic efficiency of the process. Therefore, the goal of this project is to rapidly increase the process speed: on the one hand, by consistently using galvo scanners to move the laser beam on the stationary workpiece and, on the other hand, by using multiple laser foci simultaneously.