CeraWeld

Förderkennzeichen: 49MF220074

Projektlaufzeit: 01.10.2022 bis 28.02.2025

Micro welding of technical ceramics by means of ultra-short pulse lasers

Technical ceramics are one of the highest performance material groups. Their special properties include high temperature resistance, chemical resistance, high stiffness and hardness as well as low density and thermal expansion. The need for joining processes for technical ceramics is significant due to their importance in industrial processes. The challenge here is that the joint should have the same properties as the base material, which makes the use of adhesives or solders impossible in many cases.

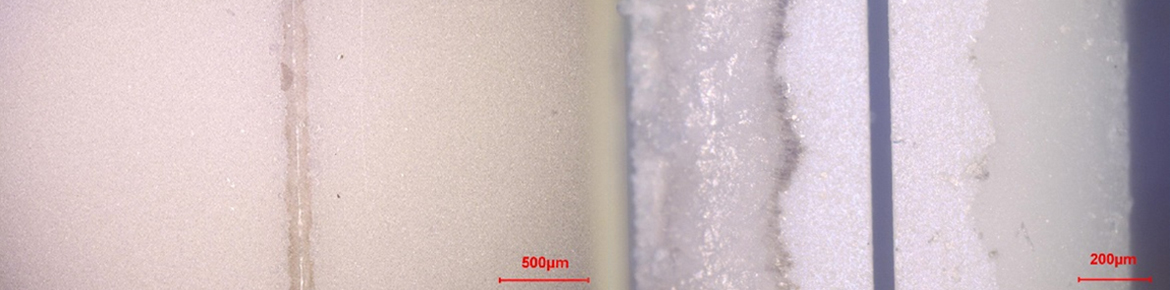

The aim of the project is to produce gas-tight welded joints on intransparent ceramics using the ultrashort pulse laser. In each case, volumes of about 20 to 100 µm in diameter are melted. These micro-welding spots are continuously placed together in such a way that weld seams can be drawn with them. The joining partners are not heated macroscopically. Since the joining zone is so small, only little energy is required to heat it to the melting temperature. The ceramics to be welded here scatter very strongly due to their microstructure, so that the welding is superficial. The project also aims to clarify which edge preparation is necessary to achieve qualitative joints.

The aim of the project is to produce gas-tight welded joints on intransparent ceramics using the ultrashort pulse laser. In each case, volumes of about 20 to 100 µm in diameter are melted. These micro-welding spots are continuously placed together in such a way that weld seams can be drawn with them. The joining partners are not heated macroscopically. Since the joining zone is so small, only little energy is required to heat it to the melting temperature. The ceramics to be welded here scatter very strongly due to their microstructure, so that the welding is superficial. The project also aims to clarify which edge preparation is necessary to achieve qualitative joints.