LADY

Förderkennzeichen: 49MF190021

Projektlaufzeit: 01.07.2019 bis 31.10.2021

Longitudinal Seam-Welding by means of lasers with dynamic beam modeling

Aim of the development

The demand for longitudinal laser welding is constantly increasing. Currently, mainly CO2 lasers are used for longitudinal welding. The main reason for this is the spatter formation associated with fiber lasers for this welding task. If it were possible to reduce this, fiber lasers would be significantly more cost-efficient in use than CO2 lasers, since they operate more energy-efficiently and thus cause lower operating costs. For example, the efficiency of fiber lasers is typically around 30 %, while that of CO2 lasers is around 10 %. In addition, with CO2 lasers there are the necessary changes of the working gas. It would therefore be desirable to have processes that allow fiber lasers to be used for longitudinal seam welding at higher speeds without the need for reworking, and this would make sense from both an operational and an economic point of view.

Advantages and solutions

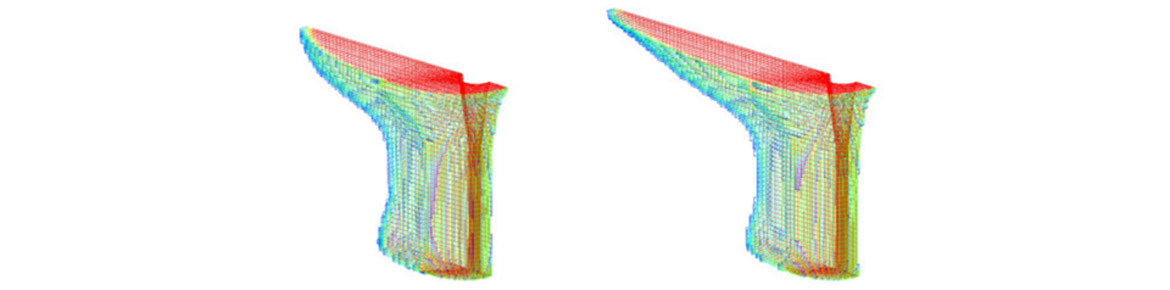

By using dynamic beam shaping, it was possible to achieve laser welds on the materials S235JR, 1.4301, as well as on AlMg3 by means of a single mode fiber laser, in which spatter formation was significantly reduced compared to the use of classical Gaussian profiles. Angular beam profiles were used for this purpose, in which the power was varied over the surface. The use of this profile shape ensures a slower flow around the keyhole and thus a smoother melt pool. The profile shapes found varied across materials as well as material thicknesses. Welding instructions were prepared for the three materials mentioned. It was further shown that dynamic beam oscillation in the direction of laser beam propagation also has the potential to improve weld quality and reduce spatter formation.

Target market

The knowledge generated from the research project will contribute to an increase in the performance of laser welding, which will lead to its widespread use. By substituting CO2 lasers with fiber lasers, more energy-efficient welding processes can be carried out. In addition, the developed process can be used with conventional single-mode fiber lasers. The acquisition of expensive multi-core fiber laser systems of the latest generation can thus be dispensed with.