LaMer

Förderkennzeichen: 49MF210037

Projektlaufzeit: 01.06.2021 bis 30.09.2023

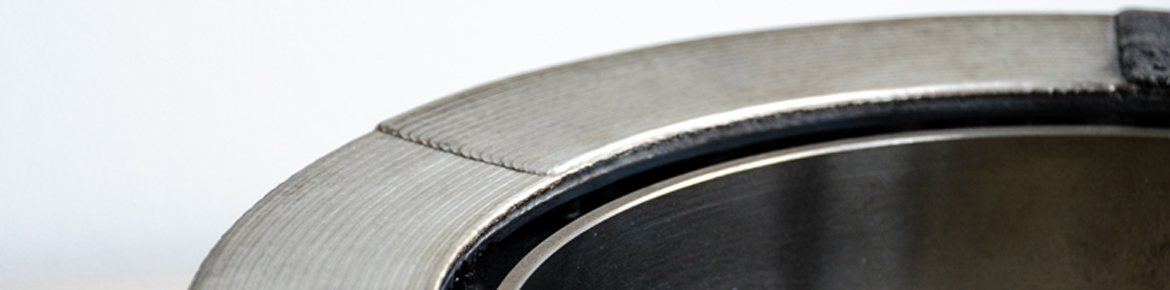

Laser deposition welding of multilayer systems on cast iron

Aim of the development

The aim of the project was to characterize grey cast iron as a substrate material in terms of material technology, to qualify the material for laser cladding as a coating process and to determine and overcome the existing difficulties in welding suitability. The material behaviour of grey cast iron as a substrate for laser cladding was characterized with the aid of multi-layer systems consisting of a buffer layer and a wear protection layer. In particular, structural changes that occur depending on the heat input during the welding process were taken into account.

Advantages and solutions

By using multi-layer systems, it was possible to determine the extensive relationships between the gray cast iron substrate and the cladding material used. This made it possible to determine the synergetic combination in which the mechanical properties of hardness can be positively influenced. The tests were used to draw conclusions as to how the energy of stretching affects the material behavior. This allows information and instructions to be derived for the industrial processing of this substrate.

Target market

Research into the interaction of gray cast iron with laser cladding is particularly suitable for the automotive industry or mining technology. In these sectors, gray cast iron materials can be used as cost-reducing substrate materials if thin wear-resistant layers are to be used. The transfer of knowledge takes place in an advisory capacity.