KorrMisch

Förderkennzeichen: 01IF00049L

Projektlaufzeit: 01.11.2021 bis 29.02.2024

Corrosion behavior of metallic foils made of similar and dissimilar material combinations

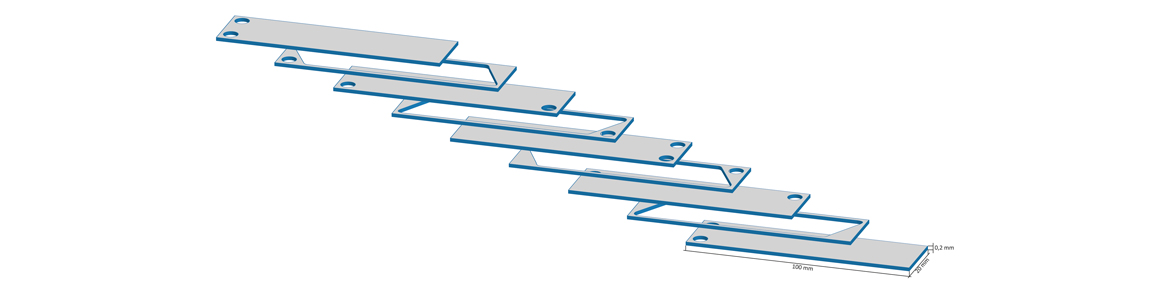

An important step towards the energy turnaround is the increased use of technologies with efficient energy utilization, such as fuel cells, electric motors or heat exchangers. All these technologies are manufactured from components consisting of several layers of structured or unstructured metallic foils. In the processing of these foils, energy-intensive manufacturing processes such as furnace brazing could be replaced in the future by more resource-saving processes such as laser beam welding. The challenge in the project is the insufficient corrosion resistance of laser welds on metallic foils. In order to better exploit the potential of laser beam welding as an efficient and easily automated manufacturing process, the development of a micro-measurement cell for determining the corrosion resistance of the weld seam is the focus of the joint research project of ifw Jena and iks Dresden.

In this context, the project is also intended to form the basis for the PUNKT project (48 LBR), in which the processing of foils by laser spot welding for rotary heat exchangers is being investigated.

In this context, the project is also intended to form the basis for the PUNKT project (48 LBR), in which the processing of foils by laser spot welding for rotary heat exchangers is being investigated.

Project partner: Institut für Korrosionsschutz Dresden GmbH